SNSTC 2021-07-20

Hydraulic control valve is a very important component in the construction machinery industry. Its function is to control and adjust the flow direction, pressure and flow of hydraulic oil in the hydraulic system, so that the actuator and its driven working mechanism can obtain the required movement direction, thrust(torque) and movement speed (rotation) etc. No matter the structure is simple and complex, any hydraulic system can not lack of hydraulic (control) valve.

There are many holes need to be finishing reamed in the hydraulic valve block of the hydraulic control valve, it is a difficulty to process these holes with high efficiency and quality in the cutting tools industry, especially some finishing reamer of deep holes.

The traditional carbide reamers usually can achieve about Ra1.6 roughness in finishing reaming for hydraulic (control) valve, the linear velocity is generally not higher than 50m/min, tool processing life is usually less than 300 pieces. For this situation, Shanghai Nagoya’s technology R&D team has designed and developed a high-speed machining scheme in brazed reamers of special flute and cutting edge with patent protection after repeated verification and trial cutting.

Compared with the traditional carbide reamer, the brazed reamer developed by Shanghai Nagoya can produce the parts with surface roughness less than Ra0.5, and has a huge improvement in processing efficiency and tool life.

Up to now, the brazed reamers of shanghai Nagoya has popularized and used in many well-known customers and end-user, which has solved the technical difficulty of finishing reaming hydraulic valve blocks in the construction machinery industry.

Application

Difficulties: the high requirements for hole tolerance and roughness , the processing effect and tool life of coated carbide reamer cannot meet customers’ requirements.

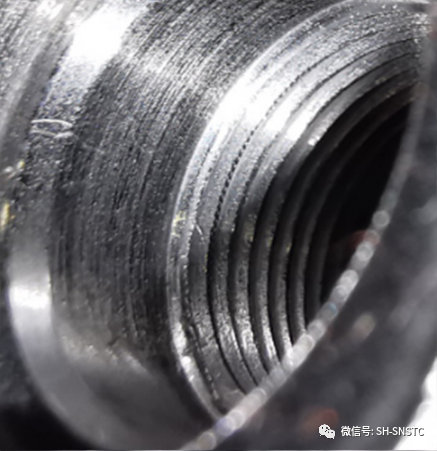

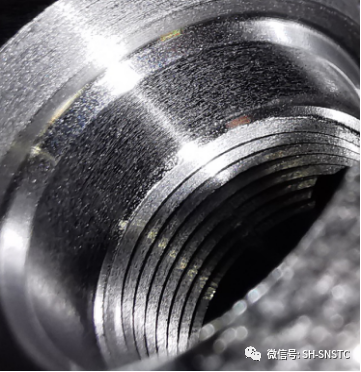

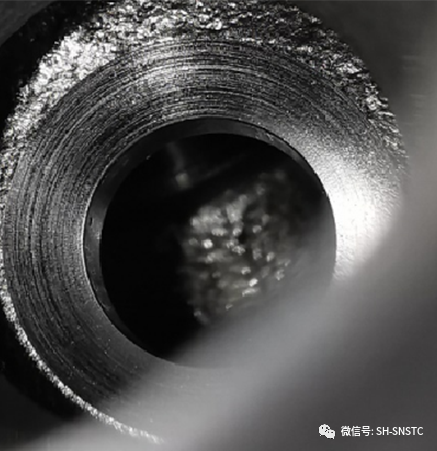

▲ A company’s carbide reamer ▲SNSTC’s brazed reamer

Through customer’s test and comparison, when our brazed reamer process the position D14.5,the hole roughness is better than carbide reamer of A company obviously, and processing efficiency and tool life are far more than the original scheme, also the processing efficiency is increased by 13.2 times, tool life is increased by 6.25 times, and the tool cost of single hole processing is reduced by 70%, it is highly approved by customer!

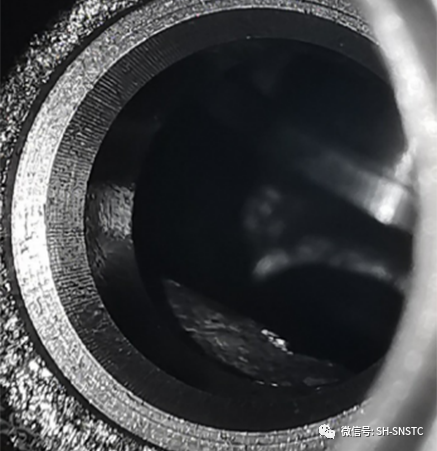

▲ A company’s carbide reamer ▲SNSTC’s brazed reamer

Through customer’s test and comparison, when our brazed reamer process the position D15,the hole roughness is far better than coated carbide reamer of A company,and also there will be no chatter in the processing. Compared with product of Company A, ours processing efficiency and tool life are greatly improved, the customer’s processing efficiency is increased by 8times, tool life is increased by 4 times, and the tool cost of single hole processing is reduced by 49%, comprehensive advantages are obvious!

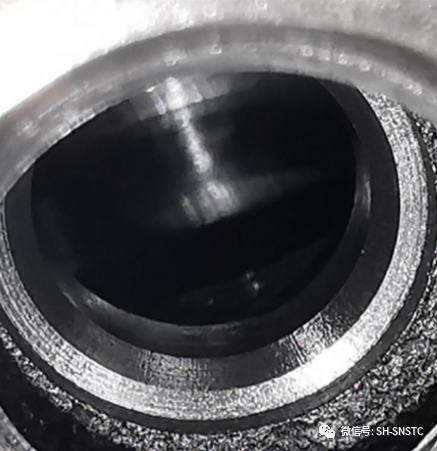

▲H company’s carbide reamer ▲ SNSTCs brazed reamer

Through customer’s test and comparison, when our brazed reamer process the position D15.8 with taper hole, the roughness of taper surpace and hole is far better than carbide reamer of H company,and also the hole diameter is stable , there is no bad taper hole during processing. The processing efficiency is increased by 10 times, tool life is increased by 2.2 times, and the tool cost of single hole processing is reduced by 54%。 Help customers to reduce costs and increase efficiency indeed!

Follow us

Follow us