Technical Sharing |How Machine Stability Affects Vibration

SNSTC 2025-07-22

In the field of machining, machine tool stability is critically important. It directly affects machining accuracy, surface quality, and production efficiency. Among the influencing factors, vibration plays a key role. The following content explores in depth how machine tool stability impacts vibration.

1.What is Vibration?

Vibration is a common physical phenomenon. In CNC machining, it refers to the mechanical oscillation of machine tools and their related components during the machining process. It is usually caused by cutting forces, moving parts of the machine itself, and other external factors, accompanied by the repetitive displacement of components. It’s similar to the vibration of guitar strings producing sound, but in CNC machining, the consequences of vibration are much more complex and significant.

2.Common Causes of Machine Vibration

①Structural Issues of the Machine

Insufficient rigidity in key structural components (e.g., machine bed, column) can lead to deformation under cutting forces, triggering vibration. Think of an unstable shelf wobbling under heavy load. Poor assembly precision or gaps between parts—like loose mechanical joints—also induces vibration during operation.

②Spindle-Related Factors

Spindle imbalance is a major cause of vibration. Uneven mass distribution during manufacturing or use creates centrifugal forces at high speeds—like an unbalanced spinning top. Worn spindle bearings further exacerbate vibration by disrupting smooth rotation due to damage to rolling elements or raceways.

③Tool-Related Factors

Imbalanced tools, improper installation, and tool wear can all lead to vibration. Uneven mass distribution or incorrect installation causes unbalanced cutting forces, resulting in vibration. Worn tools alter the force transmission and distribution during cutting, increasing the likelihood of vibration.

④Improper Cutting Parameters

Improper cutting parameters (depth of cut, feed rate, cutting speed) can induce vibration. For instance, excessive depth or overly aggressive feed rates rapidly increase cutting forces, exceeding the load capacity of the machine or tool.

3.Impact of Vibration on Machining Operations

①Impact on Machining Accuracy

Vibration causes chatter marks on the workpiece surface, directly compromising dimensional, geometric, and positional accuracy. It’s like trying to draw a straight line on smooth paper with a shaking hand—the result is wavy and imprecise. Low-frequency vibration creates surface waviness, affecting tolerances and flatness, while high-frequency vibration produces fine ripples that degrade surface quality.

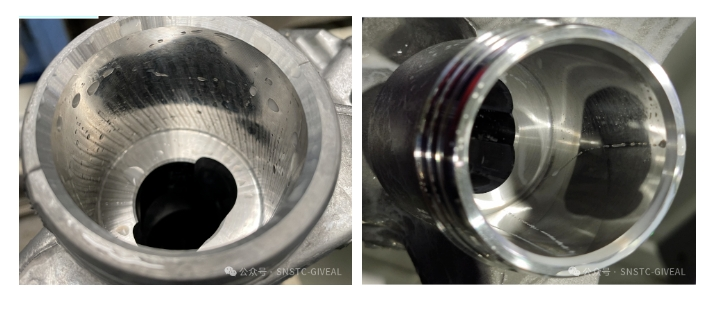

②Accelerated Tool Wear

Vibration intensifies friction between the tool and workpiece—like sandpaper repeatedly rubbing a surface—accelerating tool wear. As the tool wears, cutting efficiency drops, compromising machining accuracy, shortening tool life, and increasing replacement frequency and production costs.

③Reduced Machine Tool Service Life

Prolonged vibration damages machine components such as guideways and ball screws, accelerating wear and reducing positioning accuracy and service life. It may also cause malfunctions in electrical systems, compromising the machine’s overall performance.

4.Methods to Reduce Vibration During Machining

①Optimize Machine Structure and Components

Enhance structural rigidity through optimized design and high-quality materials for key components (e.g., bed, column) to minimize deformation under cutting forces. Use high-precision, high-performance spindles and bearings, ensuring meticulous assembly and alignment for tight fits and stable operation.

②Proper Selection and Use of Cutting Tools

Choose high-quality, well-balanced cutting tools and install them with precision to ensure proper alignment. Regularly inspect and replace worn tools to maintain cutting stability.

③Optimize Cutting Parameters

Set appropriate cutting depth, feed rate, and spindle speed based on the workpiece material, tool type, and machine capabilities. Avoid abrupt parameter changes during machining, and consider advanced techniques such as constant surface speed or variable-speed cutting to minimize vibration.

④Adopt Vibration-Damping Measures

Install anti-vibration pads between the machine base and foundation to isolate external vibrations. Use dampers or absorbers on critical components to minimize vibration response. Additionally, adopt active vibration control systems that use sensors for real-time monitoring and suppression.

In CNC machining, vibration is an unavoidable yet critical factor that greatly affects machining quality, tool life, and machine durability. By understanding its causes and effects and implementing effective vibration control strategies, we can enhance the stability and reliability of CNC operations, ultimately delivering higher-quality products. Let us prioritize vibration control, refine CNC processes, and contribute to the advancement of the manufacturing industry.

Follow us

Follow us